Hey there, crafty friend! I'm about to spill the beans on how to create the most eye-catching, vibrant designs using sublimation on white acrylic. It's like magic, but better - because you're the one waving the wand!

I've been there, staring at a blank piece of acrylic, wondering how to make it come alive with color. But then I discovered the power of sublimation, and BAM! Suddenly, I could transform that boring white surface into a work of art.

Want in on the secret? Keep reading, and I'll walk you through everything you need to know to sublimate on white acrylic like a pro. Trust me, your designs will be so vivid, they'll practically jump off the surface!

Table Of Contents:

- The Basics of Sublimating on White Acrylic

- Protecting Your Acrylic During Sublimation

- Finishing Touches for Sublimated Acrylic Products

- Creative Applications for Sublimated Acrylic

- Conclusion

The Basics of Sublimating on White Acrylic

If you're looking to take your crafting game to the next level, sublimating on white acrylic is where it's at. This technique lets you create stunning, vibrant designs that really pop. But before you dive in, there are a few key things to know. In this section, we'll cover the fundamental steps and materials you need for successful sublimation on white acrylic. Whether you're a beginner or a seasoned pro, this will give you a solid foundation to build on. First things first: you need to start with the right acrylic blank. White cast acrylic is the way to go for the most vibrant colors and crisp details. I've found that cutting the acrylic with a laser cutter gives the cleanest edges and best results. But if you don't have access to a laser cutter, you can also use a saw or scoring tool. Just be sure to sand down any rough edges for a smooth finish.

Setting Up Your Heat Press

Now let's talk heat press settings. Getting the temperature, time, and pressure right is crucial for a successful sublimation transfer. For white acrylic, I recommend setting your heat press to around 400°F (204°C). As for time, 60-90 seconds is usually the sweet spot. But keep in mind that the exact settings may vary depending on the thickness of your acrylic and the specific heat press you're using. When it comes to pressure, medium to firm pressure works best. You want enough pressure to ensure even heat distribution and a good transfer, but not so much that it warps or damages the acrylic. For me, I use 360°F for 60 seconds.

The Role of Sublimation Paper in Transfer

Sublimation paper is the unsung hero of the sublimation process. It's what actually transfers your design onto the acrylic blank. The way it works is pretty cool: when heated, the special ink on the sublimation paper turns into a gas and permeates the surface of the acrylic. As it cools, the gas solidifies and becomes a permanent part of the acrylic. That's why it's so important to use high-quality sublimation paper specifically designed for the job. Regular printer paper just won't cut it - you need paper that can handle the high heat and special ink. My personal favorites are Asub 125 gsm or Tex Print DT

Protecting Your Acrylic During Sublimation

Alright, so you've got your acrylic blank prepped and your heat press ready to go. But before you start pressing, there's one more important step: protecting your acrylic. Sublimation involves high heat, and that can sometimes lead to warping or damage if you're not careful. But don't worry - there are a few simple things you can do to keep your acrylic looking flawless. Butcher paper and Teflon sheets are your acrylic's best friends during the sublimation process. They provide an extra layer of protection against the heat and prevent any unwanted texture or marks. I like to sandwich my acrylic blank between two sheets of butcher paper, with a Teflon sheet on top for good measure. This helps distribute the heat evenly and prevents the acrylic from sticking to the heat press.

Peeling Off One Layer of Masking

Most acrylic blanks come with a protective masking on both sides. Before sublimating, you'll want to peel off one layer of this masking. This serves two purposes: it allows the sublimation ink to penetrate the acrylic, and it also protects the other side from any ink or residue during the pressing process. Just be sure to peel slowly and carefully to avoid any static cling or dust sticking to the exposed acrylic. And always handle the acrylic by the edges to avoid fingerprints.

Finishing Touches for Sublimated Acrylic Products

You've pressed your design and your acrylic is looking great - but you're not quite done yet. The post-pressing steps are just as important for achieving that perfect, professional finish. After pressing, carefully remove the butcher paper and sublimation paper from your acrylic blank. The paper may stick a bit, so take your time and peel slowly to avoid any damage. Once the paper is removed, you may notice some residue or "haze" on the acrylic surface. This is totally normal. To clean it off, simply wipe the acrylic gently with an unscented baby wipe. Avoid using any harsh chemicals or abrasive cleaners, as these can dull the finish or scratch the surface.

Weighing Down with Plywood to Prevent Warping

Even with proper protection during pressing, acrylic can sometimes warp slightly as it cools. To prevent this, I like to weigh down the freshly sublimated acrylic with a piece of plywood immediately after removing it from the heat press. Simply place the acrylic on a flat surface (I just keep it on the platen) and place the plywood on top. Let it sit for a few minutes until the acrylic has cooled and any minor warping has been corrected. This simple trick can make a big difference in the finished product.

Creative Applications for Sublimated Acrylic

One of the things I love most about sublimation on acrylic is the sheer versatility. The creative possibilities are endless. From practical items to purely decorative pieces, sublimated acrylic can do it all. Hair clips are a great example of how sublimation can elevate even the smallest accessories. By sublimating detailed designs onto acrylic blanks, you can create truly one-of-a-kind hair clips that express your unique style. The key is to use thin, lightweight acrylic blanks specifically designed for hair clips. This ensures a comfortable fit and minimizes bulk. And because the design is sublimated, it won't peel, fade, or scratch off like vinyl or other adhesives.

Expanding Product Lines with Unique Offerings

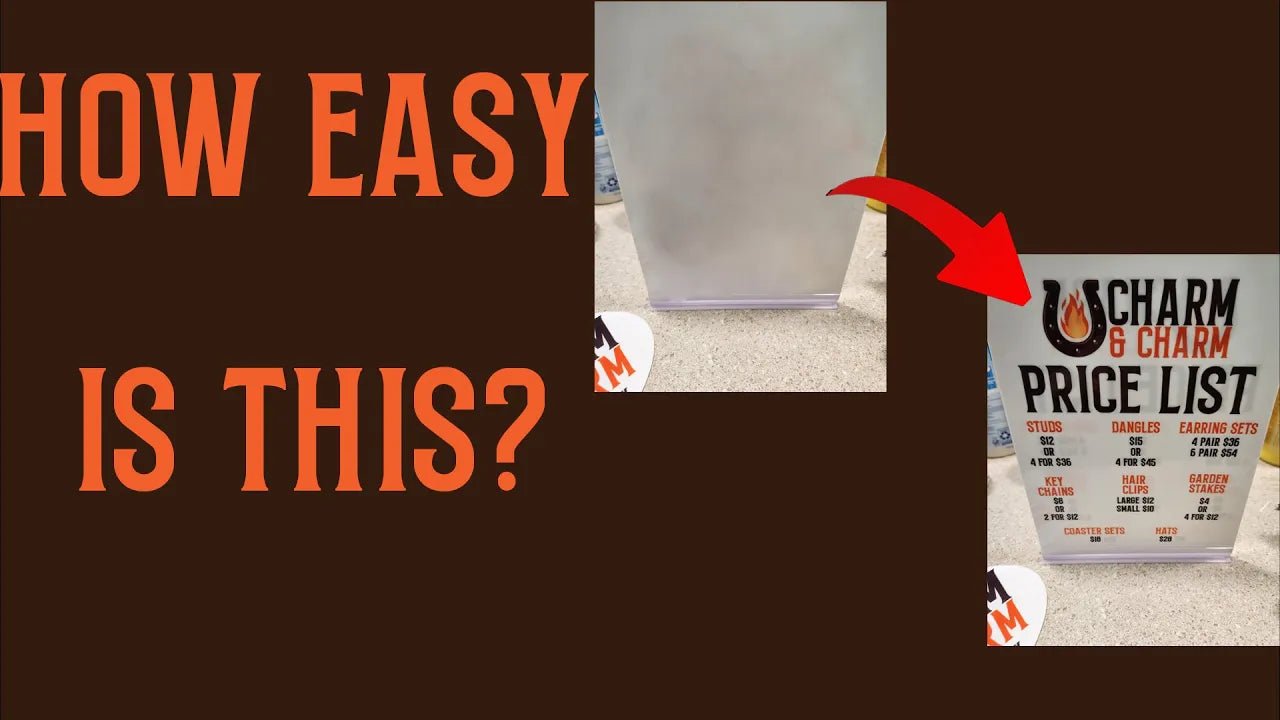

If you're looking to start or grow a crafting business, sublimated acrylic products can be a great way to stand out from the competition. By offering unique, high-quality items that can't be found elsewhere, you can attract new customers and keep them coming back for more. Some popular sublimated acrylic products include: - Nightlight blanks - Keychain blanks - Social media signs - Cake toppers - Ornaments - Bookmarks - Coasters The possibilities are truly endless. By getting creative with your designs and product offerings, you can build a thriving business around sublimated acrylic crafts.

Conclusion

Well, there you have it - the lowdown on sublimating on white acrylic. It's not as intimidating as it seems, right? With the right tools, a little know-how, and a dash of creativity, you can create stunning designs that will make your friends' jaws drop.

Remember, the key is in the prep work. Get your acrylic blank ready, dial in those heat press settings, and don't forget the importance of that sublimation paper. Once you've got the basics down, the possibilities are endless!

So go ahead, grab your favorite design, and let's sublimate on white acrylic like nobody's business. I can't wait to see the vibrant, eye-catching creations you come up with. Happy sublimating!